- PepsiCo Veurne is one of the largest production sites for crisps in Europe

- West Flanders is classified as a high-risk water area within PepsiCo based on scientific analyses

- The Veurne site therefore aims to reduce its tap water consumption 8 times by 2030, from 3.5 liters to 0.4 liters per kg of finished product.

- That's why PepsiCo Veurne invests in the optimization of water consumption, the capture and reuse of rainwater and moisture in potatoes, and smart real-time monitoring

- PepsiCo has a partnership with Natuurpunt to restore the natural water level in the West Flemish nature reserves

- In total, PepsiCo is investing approximately 7.5 million euros in these water projects

Almost 25 years ago, PepsiCo started up the production of potato crisps in Veurne, West Flanders, where many potato growers are located. Back then, water was no cause for concern. Since then, the potato crisps factory has grown into one of PepsiCo's largest production sites in Europe. By 2021, it was producing over 80,000 tons of crisps for 13 countries in Europe. In the meantime, the circumstances have also changed: the province of West Flanders has been suffering from severe drought in recent summers, and water must therefore be used wisely. However, the production of crisps is water intensive: to produce 1 kg of crisps, about 5.5 liters of water is needed.

New potato varieties, irrigation, and monitoring

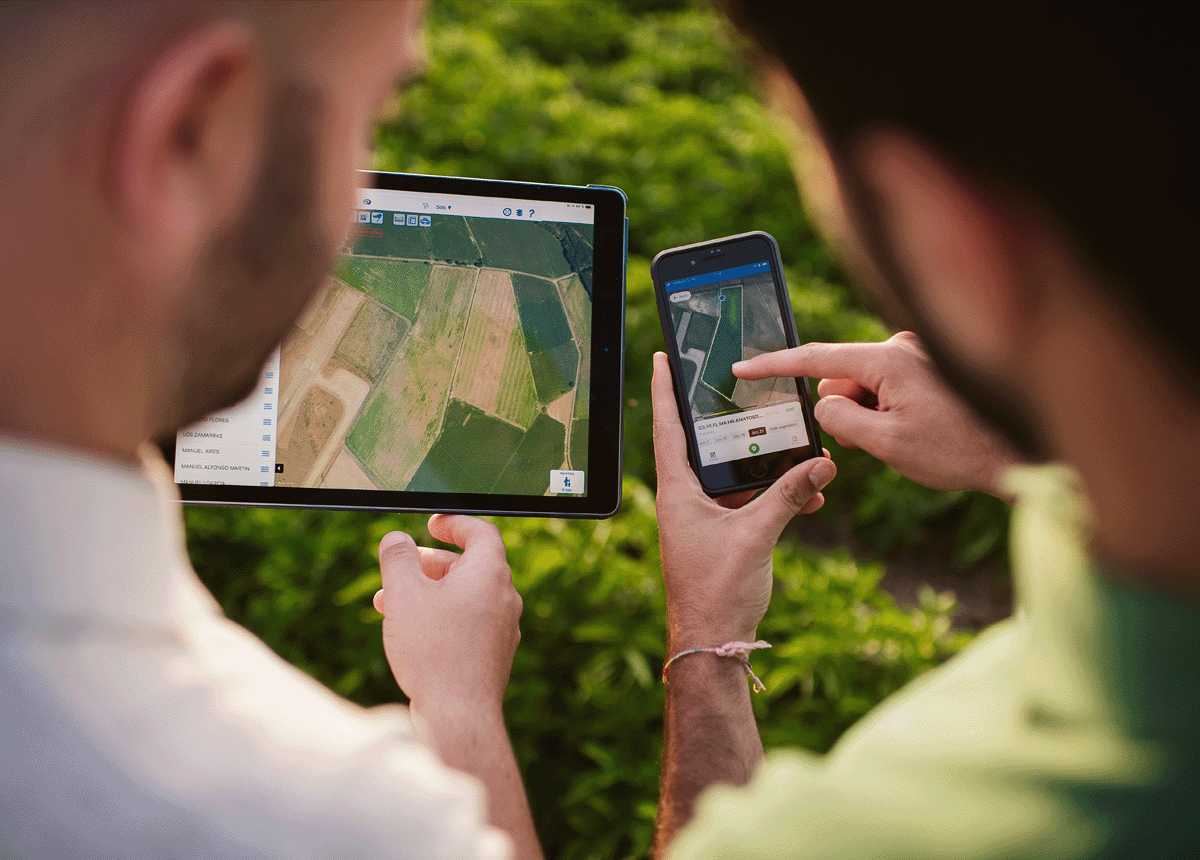

The production chain starts with the potato grower. Since the last few years have been exceptionally dry, the potato yield per hectare remained below par. In a standard year, around 45 to 50 tons per ha are harvested, but the expectation for 2022 is around 30 tons/ha. In cooperation with potato growers, PepsiCo is therefore taking several initiatives to be better able to cope with the water shortages. For example, it is developing potato varieties that can better withstand drought and is conducting pilot projects with irrigation. It is also working with an app that closely monitors the growth of the potato crops and irrigation.

8 times less tap water

Water consumption is also being addressed at the production site. Veurne was identified by PepsiCo as a location where the shortage of water poses a risk to the environment and to production activity. Spain, Turkey, and Greece also have sites in "high water risk areas. For this type of area, PepsiCo has set strict targets internally: by 2030, only 0.4l of tap water should be used per kg of finished product. By 2025, all water that is not reused must be replenished.

Today, the production site consumes almost 500 million liters of water (purified and tap water) on an annual basis. When we talk about tap water, the factory consumes 6% of the total amount of tap water consumed in the region (half of the Westhoek) or 3.5 liters of tap water per kg of crisps. This consumption should therefore be reduced by a factor of 8, to 0.4l of tap water per kg crisps. PepsiCo Veurne has therefore drawn up an ambitious action plan to achieve this objective by 2030:

Optimizing water purification

PepsiCo Veurne has been using water purification since 1986. Due to the growth of production, more water is being consumed and its capacity needs to be increased. The installation will therefore be expanded to be able to reuse 95% of the filtered process water, almost doubling the current 50%. The expansion will be done by a membrane bioreactor, where a membrane filter separates sludge and water under pressure. The existing reverse osmosis plant will also be converted to a closed circuit.

1. Rainwater becomes drinking water

Together with several partners, PepsiCo is starting the construction of a new water network to collect, purify and reuse waste and rainwater instead of letting it run off into the sewer system. In this way, PepsiCo will collect approximately 35,000 m³ per year or 11 Olympic-sized swimming pools of rainwater from its own roofs. The new water network for the approximately 50-hectare site also protects the adjacent nature reserve and contributes to greater biodiversity. It is the largest project in the field of sustainable water management in Belgium and the largest in the Flemish government's 'Proeftuinen drought 2021' subsidy program.

2. Reuse of moisture in potatoes

A potato consists of 2/3 water and some skin. A condenser is used to collect the water vapor from the potatoes during the production process, and the condensed water is then purified for reuse. The facility will thus save about 120,000 liters of water per day (2028).

3. Monitoring

Finally, the teams at the plant are constantly measuring water consumption on the production lines, through software that uses sensors and artificial intelligence. This has resulted in water savings of more than 10% over the last 2 years.

Replenish what is not reused

PepsiCo has also set a goal within its PepsiCo Positive sustainability vision that in high water risk areas, all water that is not reused must be replenished at least 100% by 2025. As part of that goal, PepsiCo started a partnership with Natuurpunt in 2019 to invest in improving water management in West Flanders nature reserves. In the Blankaart and the Uitkerkse Polder, for example, work is being done on the construction of a system of ditches and trenches in which the flood water is led deep into the grassland during high water levels, instead of being rapidly drained into the IJzer. The project will result in more wet grounds, which is beneficial for biodiversity and for recreation. So far, 120,000 m³ of water have already been replenished in this way.

The total investment amount for all projects is 7.5 million euro.

About PepsiCo

Every day, consumers around the world, in over 200 countries and territories, consume PepsiCo products more than a billion times. PepsiCo generated net sales of $79 billion in 2021 thanks to a complementary food and beverage portfolio that includes well-known brands such as Lay's, Doritos, Cheetos, Gatorade, Pepsi-Cola, Mountain Dew, Quaker and SodaStream. PepsiCo's product portfolio encompasses a wide range of tasty foods and beverages, including numerous major brands that each have estimated retail annual sales of more than $1 billion.

PepsiCo is driven by its vision to be the world leader in 'convenience' beverages and foods by winning with PepsiCo Positive (pep+). pep+ is PepsiCo's strategic 'end-to-end' transformation that puts sustainability at the heart of how growth and value are created. This is by working within planetary boundaries and also inspiring positive change for people and planet. For more information, visit www.pepsico.com.

***

More information for journalists:

Anneleen Touquet, 0032 474 25 54 61

Janne Demaer, 0032 492 70 18 42